Concrete has fluidity because the paste comprises glue, fine aggregate, and water wrapped on the stone’s surface. The paste can act as a “lubricant” to wrap the stone to form a flowable dynamic equilibrium whole. The good fluidity of concrete requires good fluidity of the paste itself on the one hand and good fluidity after the paste wraps the stone on the other hand. Increasing the amount of fine stone will increase the total specific surface area of the stone, which means that the paste that can be attached to the stone per unit area becomes less, thus changing the flow performance of the concrete. If you want to adapt a liter of volume, 20mm stone is not suitable, and replacing it with 0.5mm stone in equal amounts will change the performance of the concrete. The best way is to reduce the amount of fine stone according to a certain proportion.

The main way to reduce friction is to make the stone particle shape as round as possible and the paste attached to the stone surface as thick as possible. This is why the fluidity of high-grade concrete is much better than that of low-grade concrete. Concrete with a grade of C60 or above can easily expand to more than 600mm, while C30 concrete has difficulty expanding to 550mm. I have developed a formula that can convert 10mm-20mm stone into 05mm stone, a tool that is invaluable in the field of construction. This formula, along with the one-liter adaptation method, can be used to preliminarily test the concrete material, providing insights into the water reduction rate and loss of the admixture required for concrete.

A. Test purpose and design

1. Assuming that the amount of cement paste attached to the surface of the stone will affect the flow state of the concrete, then keeping the amount of paste unchanged and increasing the amount of stone will lead to a decrease in the flow performance of the concrete;

2. To ensure the accuracy of our testing, it is essential to wash the stone before use. This step eliminates the influence of stone powder contained in the stone on the concrete, providing reliable results.

3. The presence of too many needle-like stones significantly increases friction, thereby affecting the concrete’s flow performance. This factor is so influential that it directly impacts the flow rate of the concrete made with more needle-like stones under the same mix ratio.

4. In the early concrete stage, the paste has a high gas content, and the tiny bubbles play a ball-rolling role while increasing the paste volume. After standing, the concrete will lose a certain amount of gas content, the ball-rolling effect will decrease, and the thickness of the paste attached to the stone surface will also become thinner. This change increases the degree of concrete loss over time.

B. Test process and data

The test process is relatively simple, and the tests are performed one by one according to the designed amount in the table. The only regret is that the test data of No. 11 without fine stone is a bit strange, and the expansion after one hour is smaller than that of No. 12. This result may be caused by the slurry sticking to the wall of the pot in the first test, which led to a reduction in the total slurry volume in the first group of tests. It may also be that 200g of fine stone increased the total amount of mortar in the No. 12 test group, which did not affect the fluidity.

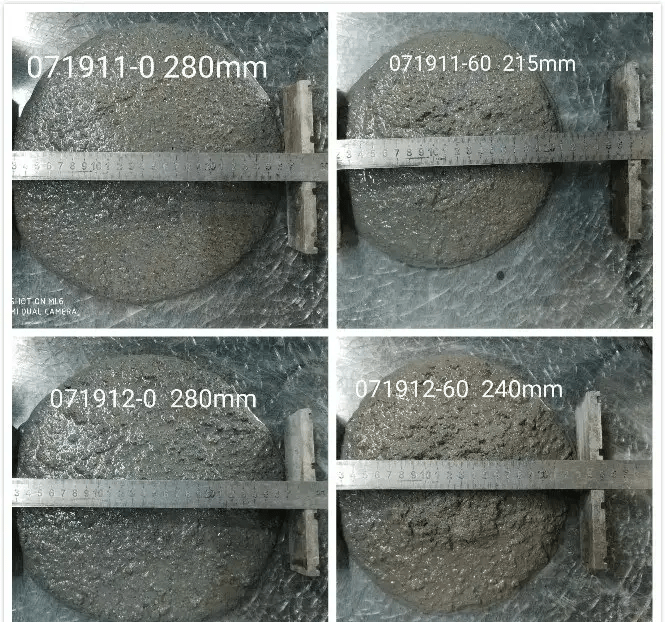

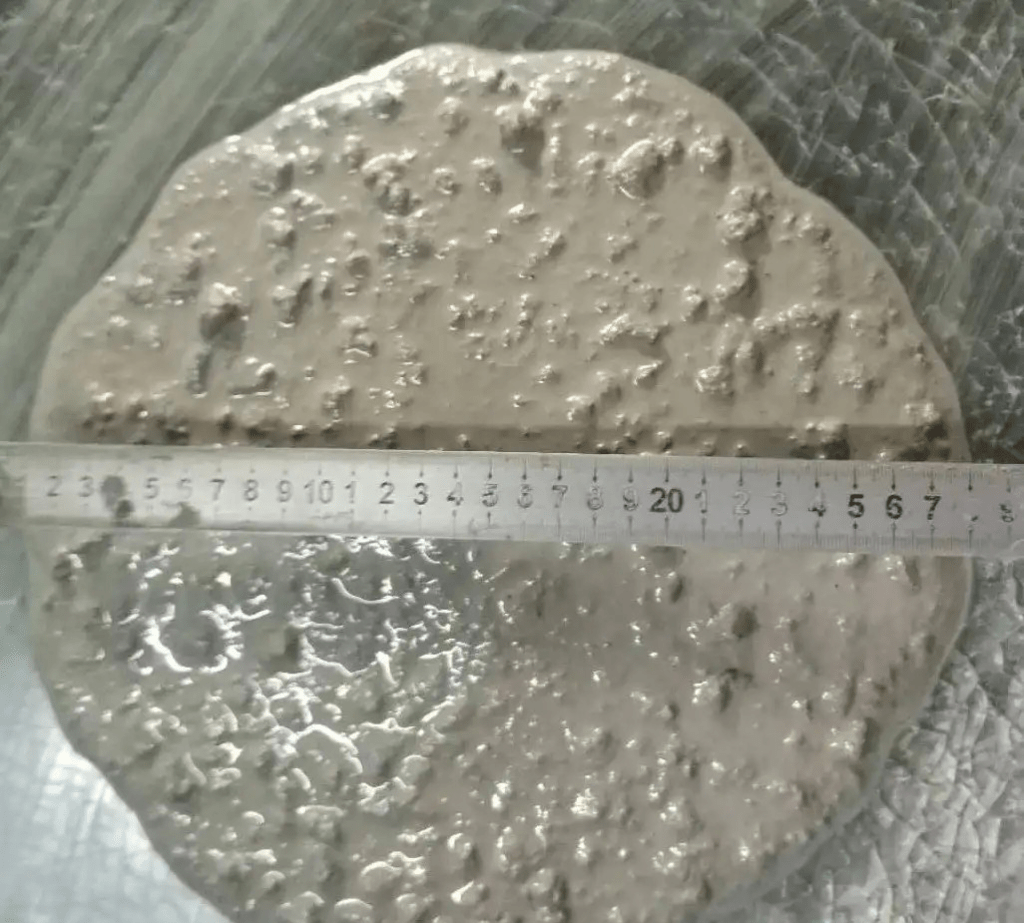

The pictures compare the expansion of Nos. 12, 13, and 14 at the beginning and after one hour. It can be clearly seen that as the amount of fine stone increases, the expansion decreases significantly.

| List | Serial No. | Fine stone dosage | Initial expansion mm | After 1 hour |

| 1 | 071911 | 0 | 280 | 215 |

| 2 | 071912 | 200 | 280 | 240 |

| 3 | 071913 | 300 | 255 | 225 |

| 4 | 071914 | 400 | 220 | 145 |

| 5 | 071915 | 533 | 280 | – |

C. Summary

1. The paste-to-stone ratio in concrete is a critical factor that must be considered. If this ratio is higher, even with a high-quality paste with good fluidity (enhanced by numerous admixtures), the issue of poor concrete fluidity can be resolved. This problem is also evident in the case of sand. When the sand grading is not optimal and the quantity is excessive, no admixture can enhance the concrete’s fluidity.

2. Water and air content can increase the paste volume, improving the concrete fluidity. The polycarboxylate water reducer itself does not have this property. Some small materials can increase the paste volume, and the macroscopic performance is to make the paste fuller. In the case of an unreasonable mix ratio, adding such small materials can improve the concrete workability and fluidity. This is the reason;

3. Artificial sand, while classified as sand in the mix ratio, contains fine stone that adds to the stone share. In mix ratios using artificial sand, the sand ratio is considerably higher than that of natural river sand. In some regions, the sand ratio can exceed 51%, which is not an optimal value for effective concrete mixtures.

4. In actual production, the change in the amount of stone is smaller than in the test. However, the total specific surface area of the stone will change due to the amount of machine-made sand, the size of the stone particles, and the needle-like shape.

Leave a comment