Reasons

1. High temperature and high amount of cementitious materials

With global warming, summer temperatures are generally higher than in previous years. The ultra-high temperature accelerates water evaporation in the concrete, especially the high-strength concrete, which has a low water-cement ratio. The evaporation of water accelerates the coagulation of the concrete. C60 high-strength concrete has more cementitious materials and is more viscous. The friction between the pipe and the concrete during pumping is much greater than that of ordinary concrete. The friction generates heat, and the temperature of the pipe and concrete rises. The hydration of concrete is accelerated when the temperature rises, the slump increases and the coagulation is accelerated.

2. The cement grinding temperature is too high

During the summer, the risk of cement dehydration is heightened due to the elevated mill temperature during the grinding process. This can lead to the production of semi-hydrated gypsum and hard gypsum. The implications for concrete mixing are significant, with the slump loss of concrete increasing and the potential for false coagulation of cement. This underscores the importance of maintaining optimal grinding temperatures to prevent such issues.

3. Laying of pumping pipelines

Some buildings occupy a large area, the pumping pipeline is very long, and there are too many elbows, which increases the resistance of concrete during pipeline transportation. There is a physical project:

- The horizontal distance is 70 meters.

- The vertical distance is more than 30 meters.

- There are 15 elbows, including 7 vertical elbows.

4. Adaptability of admixtures to cement and sensitivity to temperature and pressure

There are many types of admixtures currently sold on the market. The dosage and composition of admixtures in cement produced by different cement plants are different, and even the quality of some admixtures needs to meet national standards. In this case, the adaptability of admixtures to cement could be improved. For high-strength grade concrete such as C60, admixtures should consider their water reduction rate and their dispersibility to cement to reduce the viscosity of the mixed concrete. When pumping high-strength concrete, attention should also be paid to the sensitivity of admixtures to temperature and pressure.

Solutions

1. Glue material dosage and pumping process

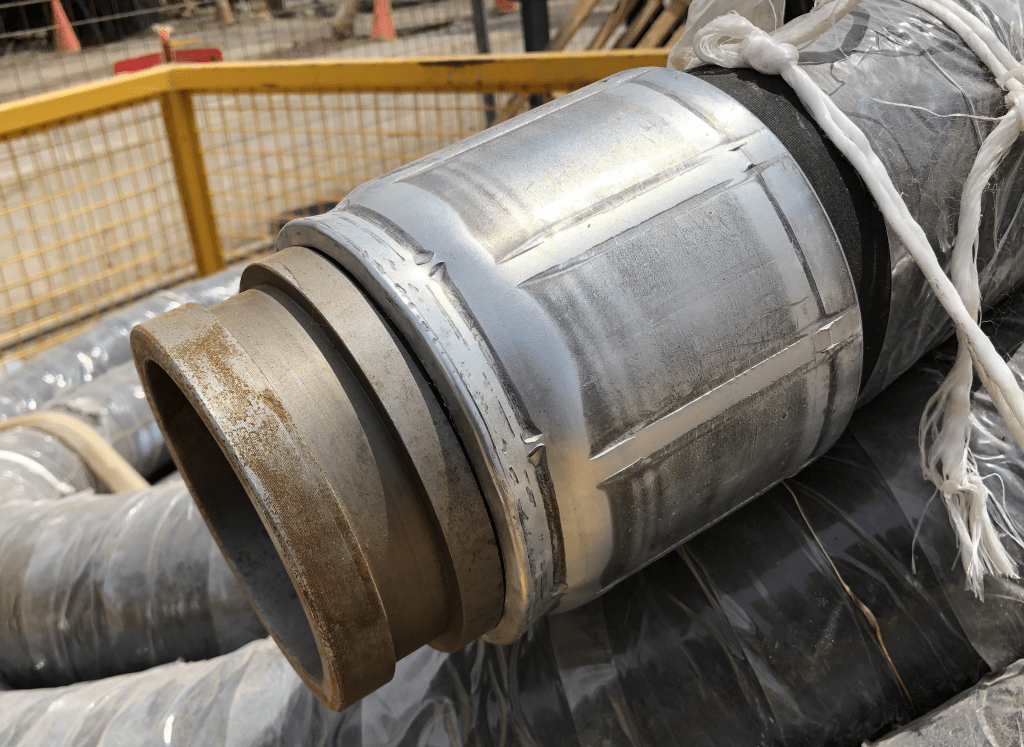

For high-strength concrete with strength grade C60 and above, the total amount of cementitious materials should be controlled at 480-560kg/m3, and the strength of cement mortar should not be lower than. In this way, the amount of cementitious materials is controlled to ensure stability, thereby preventing the viscosity of concrete. Otherwise, too much viscosity will inevitably bring difficulties to construction. During the pumping process, the temperature of the pumping pipeline increases due to frictional heat generation. Cooling treatment can be used on the pipeline, such as continuous watering or wrapping with linen cloth to water. Linen cloth has a good water absorption effect and can slow down the heating of the pipeline.

2. Selection of azurite in grinding

When it comes to the selection of azurite in grinding, it’s a step that requires careful consideration. Opt for cement with dihydrate gypsum. Hemihydrate gypsum and hard azurite can absorb water-reducer molecules, thereby reducing the dispersion effect of water reducer on cement. Therefore, it’s crucial to use dihydrate gypsum ore with a relatively simple mineral phase as gypsum for setting, and strictly control the mill temperature. Additionally, choose cement with low C3A content. The mineral components in cement have a selective adsorption effect on water-reducer molecules, and C3A and C4AF have a strong adsorption capacity. Lastly, select cement with high SO3 content. Adding a small amount of sodium sulfate to low-alkali cement will significantly improve the rheology of cement paste and concrete prepared by this cement.

3. Transportation distance and elbow setting

When high-strength grade concrete is pumped over a very high or long distance, the selection of equipment and the layout of pipelines are of utmost importance. One of the key principles is to minimize the number of pipeline elbows, especially right-angle elbows. These positions generate significant resistance during pumping. Instead, several 15° and 45° elbows can be strategically set to reduce the friction resistance during pumping. This careful consideration of the transportation distance and elbow setting can greatly impact the efficiency of the pumping process.

4. Selection of admixtures

Use aminosulfonate or polycarboxylic acid water reducers as much as possible, as they are more compatible with cement than naphthalene water reducers. When using polycarboxylic acid admixtures, you can slightly adjust the air entrainment to improve the fluidity of the concrete. On the other hand, you can change the molecular structure during the synthesis process while ensuring its fundamental indicators, such as water reduction rate, to reduce the structural damage to the polycarboxylic acid molecules due to high temperature and pressure.

Leave a comment