The purpose of concrete adaptation and admixture adaptation is to adjust the state of concrete so that it has good working performance. In short, a good condition of concrete is that it has good fluidity within 1-2 hours, the various raw materials are integrated, and there must be no separation of stones or leakage of water.

Concrete admixture adaptation is often carried out with a C30 mix ratio. The table below shows common C30 coordination ratios. Each mixing station is now optimizing the amount of latex used, which is less than 380kg/m³, such as 350-370kg/m³.

| Cement | Mineral powder | Coal ash | Sand | Stone | Water consumption | Dosage of admixture | |

| Unit(g/liter) | 220 | 80 | 80 | 800 | 1050 | 170 | 2.00% |

| 10 liter | 2.2kg | 0.8kg | 0.8kg | 8kg | 10.5kg | 0.17kg | 75g |

The more materials are weighed each time, the more the concrete adaption performance is consistent with actual production. It’s just that too many weighing materials increase the workload of the staff. Most of the concrete in each plate is 10 liters to 25 liters. The amount of admixture = the % of admixture/adhesive material * 100%. For example, the amount of admixture in one liter of concrete in the table above is (220g + 80g + 80g) * 0.02 = 7.6g. Generally, the additional dosage for 10 liters of adaptation is (220g+80g+80g)*0.02*10=76g.

Pour all the raw materials into the mixing pot individually, turn on the mixer, and add water and additives while stirring. Finally, some admixtures and water (10%-20%) remain until it is observed whether the concrete has reached saturation and then added appropriately.

There will be a sizeable experimental error in the first plate of concrete adaptation. The mixing paddle in the mixer will form a significant gap in the inner wall due to years of wear and tear, causing the concrete slurry to remain on the inner wall. The poured concrete is missing part of the slurry, making the observation unobjective. The solution is simple and crude – throw away the first concrete plate after roughly observing it, and then adapt the second plate.

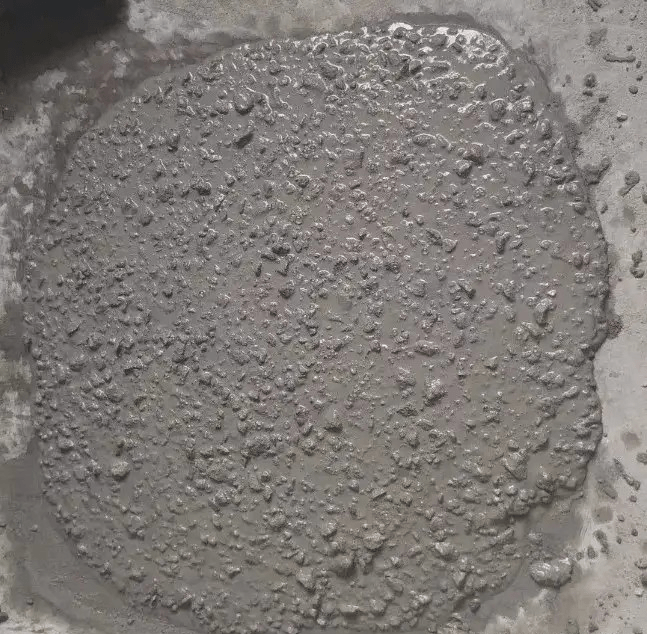

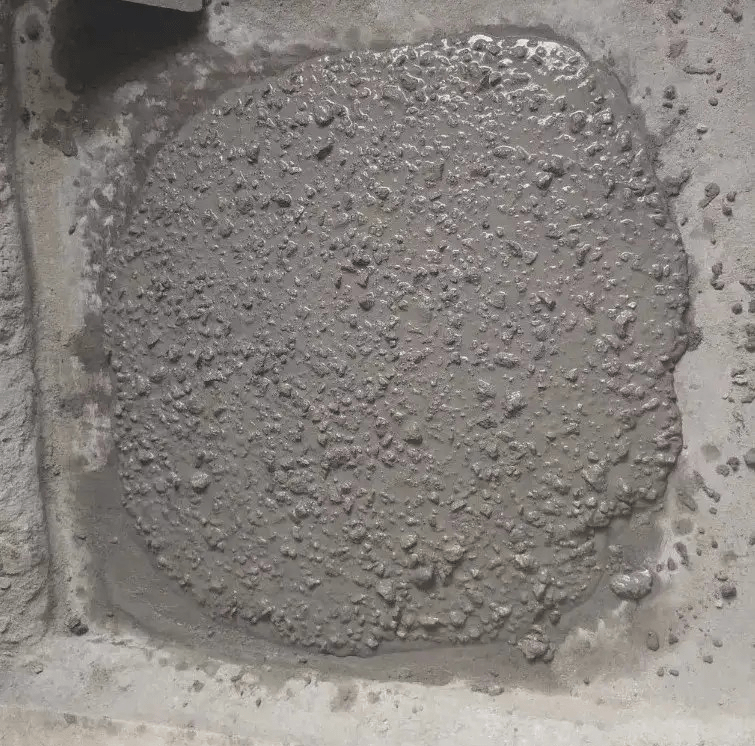

State of concrete in pot

After meeting the initial requirements for concrete, it is also necessary to observe the “time loss” of concrete. The smaller the time loss, the better the working performance of the concrete (Figure 3). The flow rate, slump, and expansion of concrete decrease after time loss. Each region has different time losses and requirements.

If you feel that the condition of the concrete has met the requirements, you can take it out of the pot (as shown below)—currently, the “slump” and “expansion” of concrete need to be measured as required. Generally, the initial concrete slump must be 200-210mm, and the expansion is 540-580mm.

After meeting the initial requirements for concrete, it is also necessary to observe the “time loss” of concrete. The smaller the time loss, the better the working performance of the concrete (Figure 3). The flow rate, slump, and expansion of concrete decrease after time loss. Each region has different time losses and requirements.

There are many reasons why concrete is in poor condition:

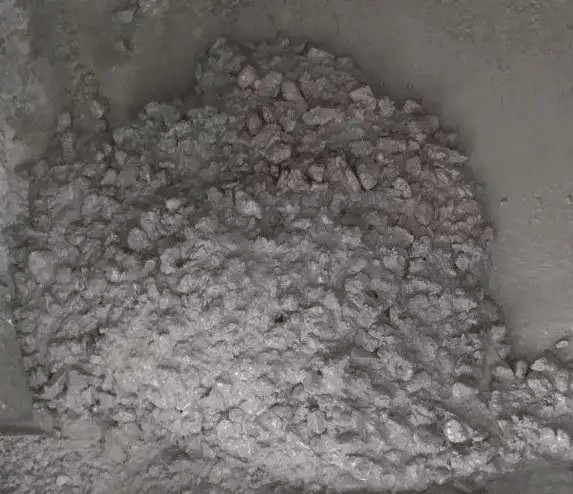

1. The concrete’s initial flow rate is slow, and the slump is minor. To solve the problem, increasing the dosage of water-reducing mother liquor is necessary.

2. The slump-preserving effect of concrete is poor. Increasing or changing the type of retarder and increasing the amount of slump-preserving mother liquor is necessary to solve the problem.

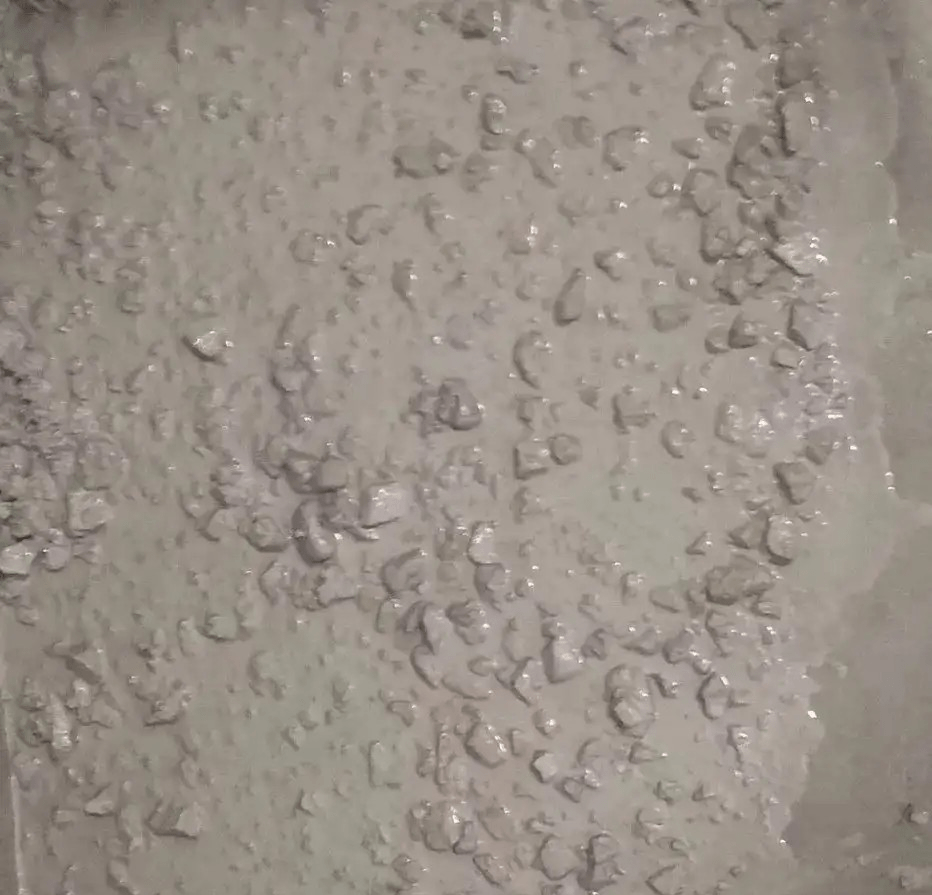

3. Concrete is prone to slurry and water bleeding; the slurry is heavy; the stone is slightly exposed. This condition can lead to structural instability. Need to add air-entraining agent to solve the problem.

4. Concrete has poor cohesion. Need to add a water retaining agent to solve the problem.

5. The concrete loses a lot after being pumped. This could be due to the type of air-entraining agent used. First consider changing the type of air-entraining agent as a potential solution.

The pictures below show the state of concrete with specific problems.

Leave a comment