The birth of concrete can be traced back to the Pantheon, built by the ancient Romans 2,000 years ago. The Pantheon’s foundation, walls, and dome are all cast in concrete made from volcanic ash. By 1756, British engineer J. Smeaton discovered when studying the properties of particular limes that harden in water that to obtain hydraulic lime, limestone containing clay (the primary raw materials of today’s cement are also clay and limestone) must be used for firing. , this vital discovery laid a theoretical foundation for the research and development of modern cement. In 1824, British construction worker Joseph Aspdin invented and patented Portland cement. He used limestone and clay as raw materials, mixed them proportionately, calcined the clinker in a vertical kiln similar to burnt lime, and ground it into cement. Because the color of the cement after hardening is identical to the stone used for construction in Portland, England, it was named Portland cement. It has excellent construction performance and is of epoch-making significance in the history of cement. In the 20th century, while continuously improving the properties of Portland cement, people successfully developed several types suitable for special construction projects, such as high alumina cement, special cement, etc. There are more than 100 cement varieties worldwide, and the annual cement output in 2007 was approximately 2 billion tons. The product obtained by mixing limestone and clay in proportion, calcining, and grinding is Portland cement; however, with in-depth research on cement. Specific properties of cement can be improved by mixing a certain amount of mixed materials (mineral powder, fly ash) and an appropriate amount of gypsum into Portland cement. The addition of gypsum can prevent the instant setting of cement. Therefore, pure Portland cement is generally called clinker. The author estimates that as long as you are not a cement practitioner, most people will not have access to pure clinker.

Clinker + admixture (6%-15%) + gypsum (1.8% ~ 2.5%) = ordinary Portland cement.

The most commonly used cement by commercial companies is P▪O 42.5 cement, which is ordinary Portland cement with a compressive strength of 42.5MPa in 28 days. Due to the smaller amount of mixed materials, the properties of ordinary Portland cement are the same as those of Portland cement. The slight differences are mainly reflected in slightly lower early strength, improved corrosion resistance, and heat resistance, somewhat lower heat of hydration, frost resistance, wear resistance, and carbonation resistance, which are slightly reduced. The chemical reaction between cement and water is called cement hydration.

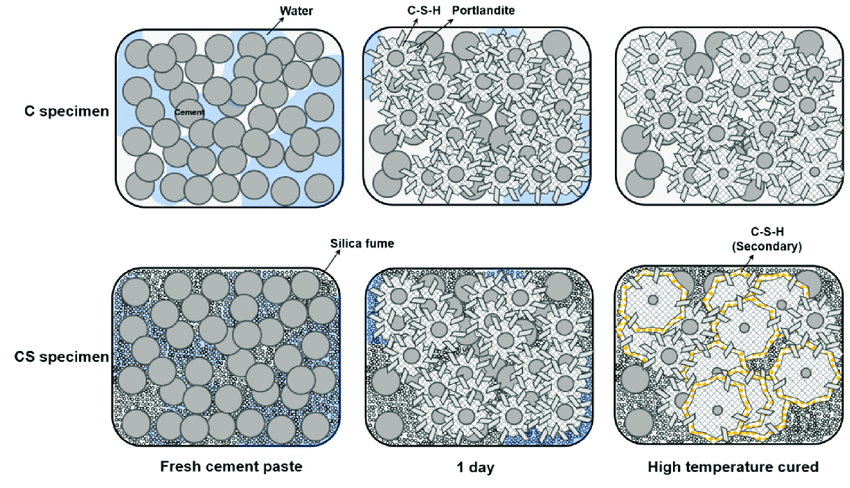

Tricalcium silicate, dicalcium silicate, and water react to form hydrated calcium silicate. The reaction process of tricalcium aluminate and tetracalcium aluminoferrite under the action of gypsum is relatively complicated. The cement hydration reaction is a continuous process divided into four stages: 1. Induction period; 2. Acceleration period; 3. Decay period; 4. Stable period.

The cement reacts sharply in the early stage of induction. Tricalcium silicate (C3S) dissolves in water and quickly hydrates and hardens, so the first exothermic peak appears. The time is very short and ends within 15 minutes. Afterward, the response is prolonged during the induction period, also known as the resting period. Generally lasts 1-4 hours. This is why Portland cement paste can remain plastic for several hours. The reasons for the quiescent period include the protective layer theory and the delayed nucleation theory. The hydrated tricalcium silicate induced to be rapidly produced in the early stage covers the surface of the cement particles and prevents further contact between water and cement. The initial setting time corresponds to the end of the induction period.

The reaction in the accelerated phase is accelerated again, and the cement particles in the stationary phase are exposed to water molecules again due to the rupture of the protective film (hydrated calcium silicate). A second exothermic peak appears; this stage ends when it reaches the peak, usually in 4-8 hours. At this point, the final setting has passed, and hardening has begun. The delayed nucleation theory is that when tricalcium silicate comes into contact with water, it rapidly hydrolyzes, and calcium ions and hydroxide ions enter the solution, thus making the original tricalcium silicate surface become “calcium deficient” or “silicon-rich.” In the surface layer, the calcium ions in the liquid phase will be adsorbed on the silicon-rich surface due to chemical adsorption, making the surface positively charged. The high concentration of calcium ions on the surface of tricalcium silicate reduces further hydrolysis of the cement, thus forming a quiescent phase in the induction phase. Calcium ions and hydroxide ions dissolve successively at a low rate. Calcium hydroxide crystal nuclei are formed rapidly when the liquid phase becomes supersaturated, concerning calcium hydroxide. When calcium hydroxide crystals grow, they will reduce the calcium and hydroxide ions in the solution, so hydration returns to the accelerated phase. The protective layer theory and delayed nucleation theory are still controversial.

In the decay period, the reaction rate decreases with time because as hydrates accumulate around the cement particles, the hydration of tricalcium silicate (C3S) is hindered, so the hydration changes from an acceleration process to a deceleration process. Lasting approximately 12-24 hours, hydration is gradually controlled by diffusion rate.

The reaction rate in the stable phase is meager. The initial product, hydrated calcium silicate, grows on the surface of the cement particles. Later, water molecules need to penetrate this layer of hydrated calcium silicate and enter the interior of the particles to continue reacting with the unhydrated tricalcium silicate. The hydration reaction is entirely controlled by diffusion rate.

The final hardened cement slurry is a heterogeneous multi-phase system consisting of a solid phase composed of various hydration products and unhydrated clinker, voids, water, and air existing in the voids. The hardened cement slurry is a porous body composed of three phases: solid, liquid, and gas. The relative content of various hydration products is as follows: C-S-H gel (hydrated calcium silicate) accounts for 70%, Ca (OH) 2 accounts for 20%, ettringite, and monosulfide calcium sulfoaluminate hydrate account for about 7%, incomplete The hydrated residual clinker and other trace components are about 3%.

The final hardened cement slurry is a heterogeneous multi-phase system consisting of a solid phase composed of various hydration products and unhydrated clinker, voids, water, and air existing in the voids. The hardened cement slurry is a porous body composed of three phases: solid, liquid, and gas. The relative content of various hydration products is as follows: C-S-H gel (hydrated calcium silicate) accounts for 70%, Ca (OH) 2 accounts for 20%, ettringite, and monosulfide calcium sulfoaluminate hydrate account for about 7%, incomplete The hydrated residual clinker and other trace components are about 3%.

Leave a comment